Copyright © 2019 Shandong Huafu Group 鲁ICP备19025546号-1 Powered by www.300.cn

Phone:+86-531 80957228/80952018

E-mail:sales@jnhuafu.cn / info@jnhuafu.cn

Zip code:250217

WhatsApp:+86-18563713664

ADD:Guanzhuang Town, Zhangqiu District, Jinan City, Shandong Province, China

Contact information

Grinding Steel Ball Classification and Introduction

Grinding steel balls, also known as grinding media balls. The main purpose is to grind materials to make them finer to meet the standard of use. They are mainly used in mines, power plants, cement plants, mill factory, silica sand factories, coal chemical industry and other fields. The annual consumption of steel balls in the world is 30-50 million tons.

There’re three types of the grinding steel balls, including forged steel ball, casting steel ball and hot rolling steel ball.

The forged steel ball is made of steel rod is cut into sections and then forged with an air hammer. The wear resistance of the forged steel ball has a lot to do with the material of the round steel and the quality of the round steel.

In cast steel balls, chromium alloy is the main component of cast steel balls. The higher the chromium content, the more wear-resistant it is. In general, the casing steel ball is divided into low chrome casting steel ball(Cr=1-3%), medium chrome casting steel ball(Cr=4-6%) and high chrome casting steel ball(Cr=≥10).

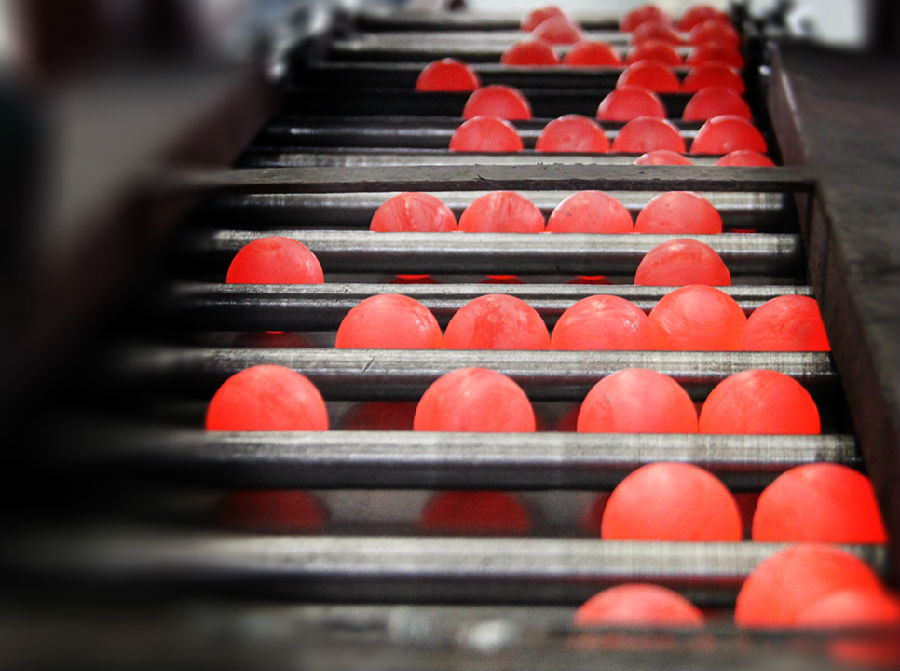

Hot rolling steel balls are produced by hot rolling production lines. In recent years, they have risen rapidly, not only with high production efficiency, but also with enhanced wear resistance. the whole process is automatically controlled, the hardness of the hot rolling steel ball is uniform, the hardness of the core is high, the crushing rate is low, and the impact value of the steel ball is large.